Sustainable and High-Performance MDF Coating Solutions with Tianke UV Resins

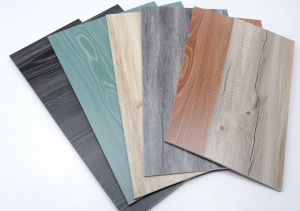

Medium Density Fiberboard (MDF) has established itself as a popular material in the furniture and interior design industries. Praised for its affordability, smooth surface, and versatility, MDF is widely used in applications such as furniture, cabinetry, flooring, and wall panels. However, MDF surfaces often require advanced coatings to boost durability, protect against environmental factors, and deliver visually appealing finishes.

With the rapid growth of UV coating technology, manufacturers now have access to a faster, more eco-friendly, and highly efficient finishing solution. UV coatings are not just limited to wood substrates—they have become increasingly popular for melamine resin, PVC/SPC, MDF/HDF boards, and more. These coatings provide exceptional performance, design flexibility, and meet the rising demand for sustainable and high-performing materials in the market.

Tianke’s Tailored Solutions for MDF Coatings

At Tianke Novel Materials, we understand the unique challenges of coating MDF surfaces. From the need for strong adhesion to smooth surfaces, to delivering enhanced durability and finishes, our UV oligomers and monomers are engineered to meet these demands while driving innovation in MDF applications.

Here are some of the key UV products we recommend for MDF coating formulations:

Adhesion Primer - TK3204+T-201+TK3208

TK3204:self-adhesive resin

T-201: Adhesion promoter, adding a small amount can significantly improve the adhesion, mainly for wood paint, the recommended proportion is 0.5-2%

TK3208: Low shrinkage, can effectively reduce costs

Putty/Base Coat - TK2202A+TK3208

TK2202A: standard epoxy acrylate with 20%TPGDA

TK3208: Low shrinkage, can effectively reduce costs. It is recommended to add a ratio of 10-25%

Top Coat, matte - TK2219+TK4308A+TK5202

TK2219: Similar curing speed and gloss of standard epoxy acrylat (TK2202A), but with excellent flexibility and tensile strenght, easy to matt.

TK4308A: Low viscosity, low gloss, the gloss of film forming alone is 3 °

TK5202: good toughness, the addition is around 8~10% to improve the flexiblity and hardness of the coating film

note: if the formula cannot meet the requirements of hardness and scratch resistance, then add some hexaacrylate polyurethance, such as TK4601 and TK5601.

Top Coat, Glossy - TK2202A+ TK4601/TK5601

TK2202A: standard epoxy acrylate with 20%TPGDA

TK4601/TK5601: Hexafunctional polyurethane, fast curing, high hardness, of which TK4601 is aliphatic while TK5601 is aromatic. The disadvantage of TK560 is poor yellowing resistance, but the price is lower.

Top Coat, Color/white - TK2216/TK3403 +TK3302

TK2216: Its yellowing resistance, pigment wettability is slightly better than standard epoxy, and the price is not far from standard epoxy, suitable for general white paint

TK3403: Super yellowing resistance, good weather resistance, suitable for white paints that require whiteness

TK3302: Used in combination with the formula, it has hardness and yellowing resistance

Tianke UV for MDF Coatings

Coating MDF with Melamine Paper

For MDF surfaces with a layer of melamine paper pressed onto them, Tianke offers specialized UV solutions that ensure excellent adhesion and performance, even on the dense and chemically stable surfaces of melamine resin.

Learn more about our UV solutions for melamine surfaces, please visit our blog Tianke Polymer’s UV Resin for Melamine Surfaces UV Coatings .

Why Choose Tianke?

With a commitment to quality, performance, and innovation, Tianke Novel Materials delivers tailored solutions to help you overcome technical challenges in MDF coatings. Our UV oligomers and monomers are designed to support efficient processing, eco-friendly production, and premium finishes for your applications.

Let’s Drive Your Success in MDF Applications

Are you ready to take your formulations to the next level?

Contact us today to learn more about our UV solutions, request technical support, or order samples for testing. Let’s collaborate to meet the growing demands of MDF applications and revolutionize the UV curing industry together!