From Challenge to Solution:

– Tianke Polymer’s UV Resin for Melamine Surfaces UV Coatings

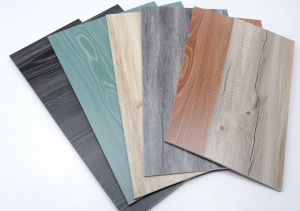

Melamine-faced boards are created through a high-temperature pressing process, bonding melamine-impregnated paper onto substrates like MDF, chipboard, multi-layer plywood, and more. These melamine papers feature a variety of exquisite patterns and designs, offering excellent decorative effects that meet consumer demands for aesthetics in decoration. Additionally, melamine-faced boards are renowned for their wear resistance, high-temperature resistance, corrosion resistance, and waterproofing properties. These attributes have made melamine-faced boards increasingly popular in the building decoration market, particularly for custom furniture, panel furniture, and office furniture.

With the maturation of UV curing coating technology, an efficient and energy-saving coating process has been developed for melamine decorative veneers. This process offers significant advantages, including high gloss, good wear resistance, and high hardness. However, melamine resin is a highly chemically stable material. The melamine decorative veneer surface is coated and cured at high temperatures to form a dense film, making it very challenging to apply coatings to its surface. Generally, UV coatings struggle to achieve the required adhesion on these surfaces.

Adhesion, therefore, presents a significant technical challenge for UV coatings based on melamine substrates. Ensuring that coatings properly adhere to the surface is crucial for achieving the desired protective and decorative effects.

At Tianke Polymer, we have developed a specialized solution for melamine substrates to address this challenge. Our recommended adhesive layer consists of the following components: TK4221+TK5202/TK3208+T-201.

Our carefully formulated combination of these UV oligomers ensures that UV coatings can achieve the necessary adhesion, gloss, and durability on melamine-faced boards. Whether you are producing UV coatings for custom furniture, panel furniture, or office furniture, our products can help you meet the high standards demanded by today’s consumers.

If you’re looking for reliable and effective UV coating solutions for melamine-faced boards, Tianke Polymer’s products are your ideal choice. Contact us today to learn more about how our advanced formulations can enhance your production processes and product quality.